& Refrigeration Services

Authorized Service Center

HVAC Services & Repair

Located in St. Petersburg, The Yacht Rigger are ABYC (American Boating and Yacht Council) Electrical Certified in both Electrical as well as Heat Ventilation and Air Conditioning. We are also EPA Certified for HVAC. Our technicians have been factory trained on the most common brands of air conditioning and refrigeration appliances commonly found in the marine industry. We utilize state of the art tools, are knowledgeable, trained and experienced, ready to assist you

Working with all major brands for marine industry refrigeration and air-conditioning

Services Offered

Refrigerant Charge

Leak detection and repair, refrigerant recovery, deep vacuum, recharge

Our team are experienced in designing and installing new and replacement systems utilizing cutting edge products to best serve your needs.

Follow up Request Form

New Equipment Sales & Installation

Sizing Your Air Conditioning System

Properly sizing the AC system is the most important step when choosing a new one. An undersized load will be uncomfortable and will make you unhappy when using it on hot days. Significantly oversizing the system will result in system “short cycling” making it less energy efficient, the biggest amperage draw of a single speed compressor is when starting, and it won’t have enough run time to satisfactorily dehumidify the vessel.

It takes about 15 minutes of runtime before you start getting proper dehumidification of the air, if the AC comes on, runs 10 minutes or less, and then shuts off, the indoor humidity levels will stay high, probably over 60%. Twenty minutes of run time would be OK. Thirty minutes per cycle or longer, will keep the humidity levels fairly low.

Capacity

Air conditioning systems are rated in BTU (British Thermal Units), a universal measure of heating and cooling.

To calculate your needs divide your boat into three basic load areas:

- Below Deck – cabins where the hull slopes inward toward the keel and there are minimal port lights and hatches

- Mid Deck – areas on the main deck with small or shaded windows

- Above Deck – areas with large glass surfaces and direct sunlight

Measure the length and width of each room to be conditioned to determine the square footage. It is assumed that your boat has average headroom of about 6-1/2 ft. (2m) and you have an average amount of furniture. If one end of the compartment is narrower than the other, take your measurement in the middle.

Now, using the BTU table, multiply the area of each cabin by the appropriate load factor to find the required air conditioner capacity.

|

BTU Formula |

|||

|

BTU’s per Square Foot |

|||

|

Climate |

Below deck |

Mid Deck |

Above Deck |

|

Temperate |

60 |

90 |

120 |

|

Tropical |

90 |

120 |

150 |

Temperate: 95°F (35°C) air, 85°F (35°C) water, moderate humidity.

Tropical: 105°F (41°C) air, 95°F (35°C) water, high humidity.

For example, 160 sq. ft. below deck cabin in temperate climate:

160 sq. ft. X 60 = 9,600 BTU’s

BTU’s calculator online https://www.marinaire.com/category-s/28.htm

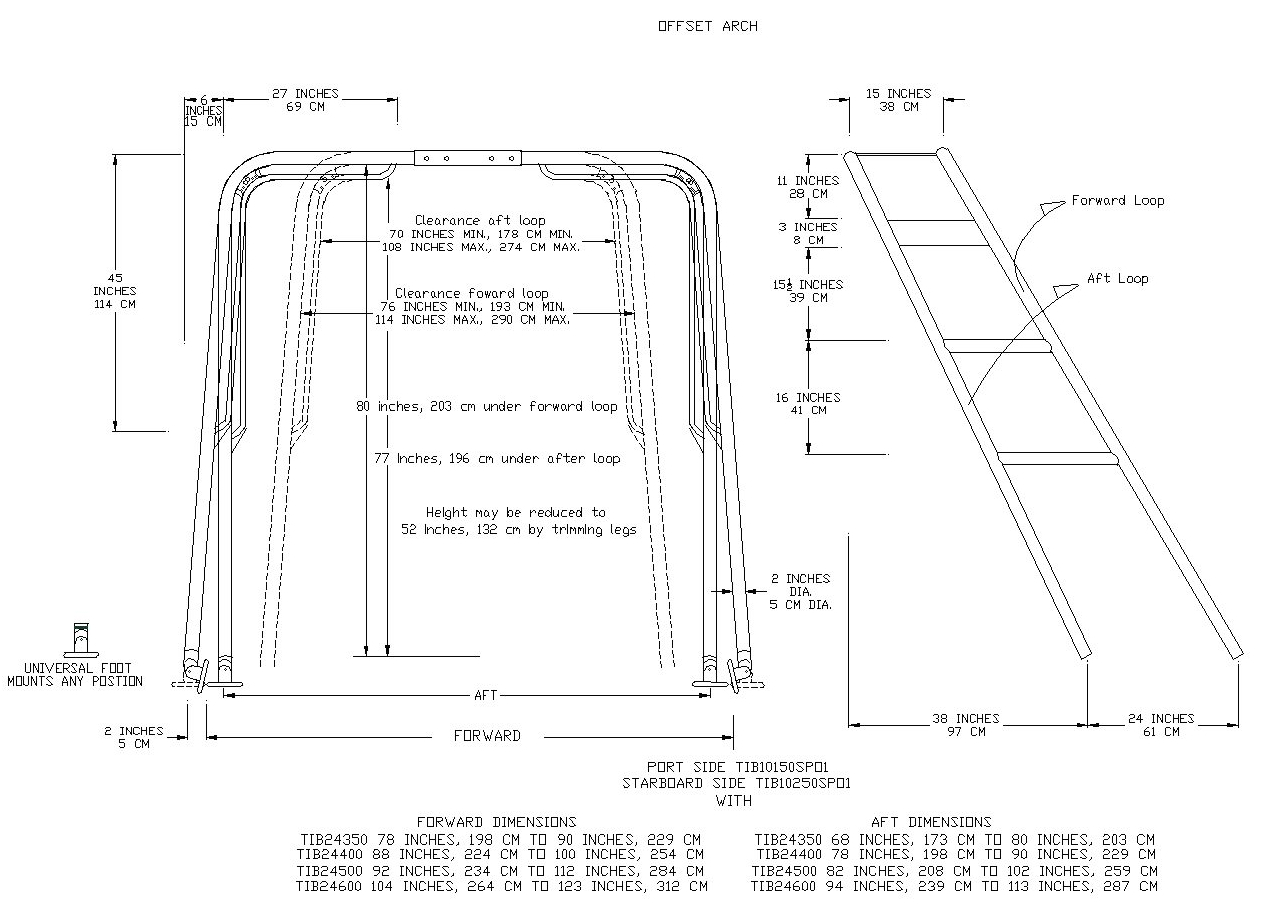

Number Of Units & Location

The size and layout of your vessel will determine the number of units that you need or can install and its location. When designing an air conditioning system, the biggest handicap is finding a location where to fit the unit itself, and finding paths for the ducting and plumbing. Some manufacturers recommend a maximum ducting run of 15 ft, and reduce it if there are many bends on the overall length to ensure good airflow. Always refer to the unit specifications sheet when planning an installation, keep in mind that by reducing the supply air flow, the return flow gets also compromised. Not having enough air passing through the evaporator will affect the unit performance and eventually lead to a complete blockage of the air due to ice formation.

In marine applications flexible ductwork is the most common, and it’s recommended to be insulated to minimize the heat transfer and avoid condensation. This type of duct, compared with the rigid one, creates a lot of turbulence, and as a rule of thumb, you want to keep it as short, straight and large in diameter as possible, and properly secured to avoid pinching or collapsing.

Duct sizing will vary according to the rated BTU output of the air conditioning unit, and those ducts must be routed to a properly sized grill that supplies the cool air to the cabin. The return air grill does not need to be directly in front of the unit, in fact, the system will be less noisy if there is an indirect path for the return air to follow. If a return duct is used, it has to be 20% larger in diameter than the cool air supply duct. This also implies a difference in the sizing of the grille used for the return that has to be larger. Another recommendation is to use wooden frame grilles for the discharge air flow to minimize condensation.

Determine the proper duct diameter and grille sizes for your air conditioning system using the next table based on the system’s BTU capacity.

|

Capacity (BTU/hr) |

Duct (in) |

Return air grille (sq in) |

Discharge grille (sq in) |

|

5,000 |

4” |

60 |

30 |

|

7,000 |

5” |

80 |

45 |

|

10,000 |

6” |

100 |

60 |

|

12,000 |

6” |

130 |

70 |

|

16,000 |

7” |

160 |

80 |

|

18,000 |

7” |

200 |

100 |

Volume air movement is important. With a heat pump installation, the normal amount of acceptable air flow through the indoor coil is considered to be 400 cfm (cubic feet per minute) per ton (12,000 BTU).

When choosing a location for a new installation make sure that there is sufficient space to service the unit and remove if necessary.

In an ideal world, not always the case, you would have each area of the boat with a different unit or air handler controlled by its thermostat. This requires a lot of space used for the installation, reducing the amount of storage space available, has a higher power demand and is expensive. Having one unit cooling more than one area is a normal situation, on this type of installation consider which one will have the temperature controlled by the thermostat and which one/s will be the secondary one/s. On those last the temperature control is achieved by controlling the air flow with adjustable grills.

Consider which areas require independent thermostat control, and which cabins will be served by ducting or a secondary air handler (where the only temperature control is by reducing airflow with an adjustable grill). In many installations we have designed systems that will cool the main salon during the day and in the evening divert more air to the staterooms, by using multiple ducting with dumpers or closeable grills, This way you can have a single system accomplishing what you would typically need two systems for, saving you space, money and using less energy.

undefined

Type Of Units

Most marine air conditioners can be divided into 2 main categories: self-contained, and remote air conditioning units, those last ones are divided in split air conditioners systems and marine chiller systems. All these systems have one thing in common, they use the surrounding water to remove the interior heat, and each has pros and cons.

Split Units

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.